-

碩士生

-

-

-

-

-

-

-

林承翰

Email:jspss95175@gmail.com

研究領域:

Micro Combustion and Power System

- Design of Micro Combustion System - Stainless-Steel and Platinum Tubular Reactor

- Catalytic Combustion of Bio-Syngas over Platinum Surface

- CFD Simulation

- Optimization of Catalytic Combustion Efficiency by Using Surrogate Model

研究成果:(展開資料)

-

賴柏佑

Email:willywillywilly1115@gmail.com

研究領域:

Electric Propulsion System

- Vaccum Arc Thruster

- Vacuum Cathode Arc Thruster with Parallel Electrode Array

- Plasma Measurement System - Triple Langmuir Probe, Fast Faraday Cup

- Inductive Storage Circuit

研究成果:

-

-

許慎恩

Email:wayne12511@gmail.com

研究領域:

Micro Combustion and Power System

- Design of Micro Combustion System - Stainless-Steel and Platinum Tubular Reactor

- Catalytic Combustion of Bio-Syngas over Platinum Surface

- CFD Simulation

- Optimization of Catalytic Combustion Efficiency by Using Surrogate Model

研究成果:

-

-

-

-

-

-

-

-

-

-

-

-

博士生

-

-

-

王彥儒

Email:wangyanru428@gmail.com

研究領域:

Biomass Energy and Technology

- Biomass Gasification Micro Combined Heat and Power System

- Demonstrating a Small-Scale Decentralized CHP system

- Optimization of CHP System Performance by Using Surrogate Model

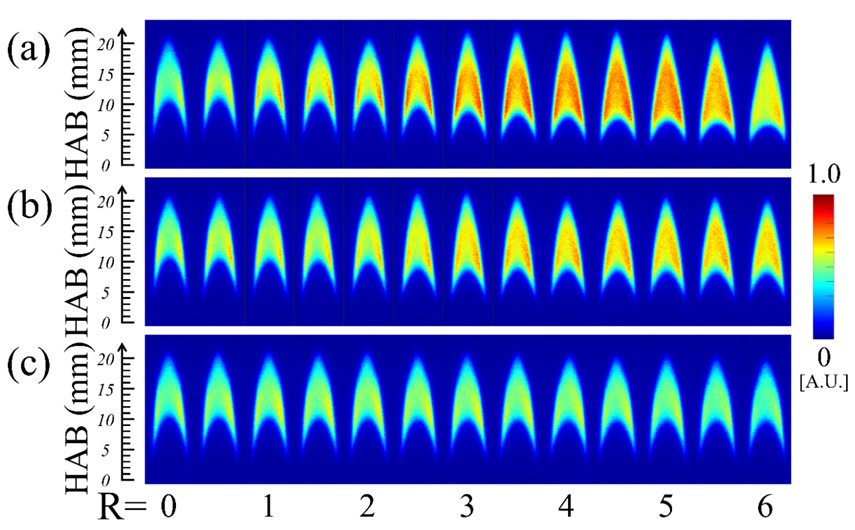

Flame and Combustion Science

- Amonia/Metal Combustion

- Biomass Combustion

- Laser Diagnostics Measurement on Temperature and Species Concentration

研究成果:(展開資料)

-

-

-

-

-

-

-

-

-

-

畢業生

-

-

-

-

-

-

-

-

-

-

-

干孝凱

Email:kx4011223@gmail.com

研究領域:

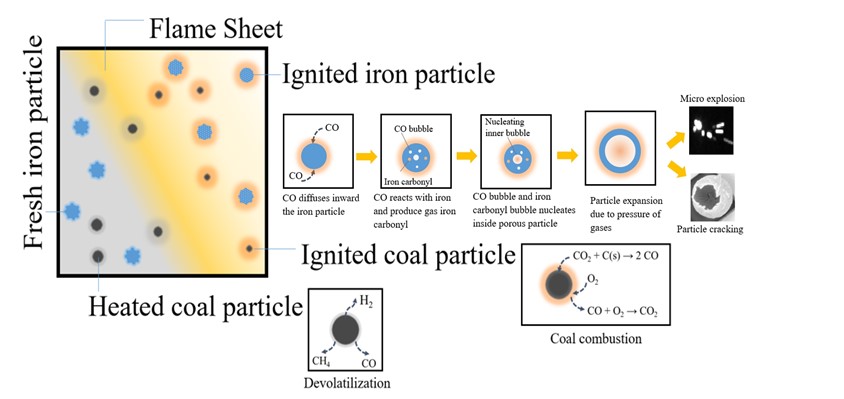

Flame and Combustion Science

- Development of Pyrolysis-Combustion-Combined Impinging Clean Coal Burner

- Improving Coal Combustion and Mitigating Pollution

- Laser Diagnostic Measurement on Soot and Temperature

- Optimization of Coal-Firing Combustion Efficiency by Using Surrogate Model

研究成果:(展開資料)

-

-

-

陳怡蒨

Email:lucario7129@gmail.com

研究領域:

Electric Propulsion System

- Radio-Frequency Ion Engine with Inductively Coupled Plasma Source

- Plasma Measurement - Retarding Potential Analyzer

- Advanced Integrated Plasma Diagnostic Package

- Optimization of Ion Thruster by Using Surrogate Model - Kriging

研究成果:(展開資料)

-

-

-

-

-

洪靖茹

Email:dodo12081208@yahoo.com.tw

研究領域:

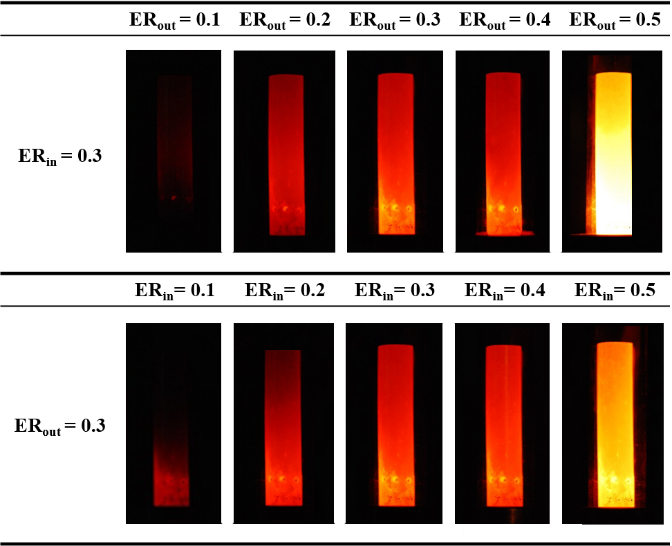

Micro Combustion and Power System

- Design of Micro Combustion System - Platinum Tubular Tube with Perforlated Hole Arrays

- Catalytic Combustion Mechanism of Syngas over Platinum Surface

- Micro Power System of Thermophotovaltic Cell Array Combined with Catalytic Reactor

研究成果:(展開資料)

-

-

-

-

-

高健鈞

Email:scott7705766@gmail.com

研究領域:

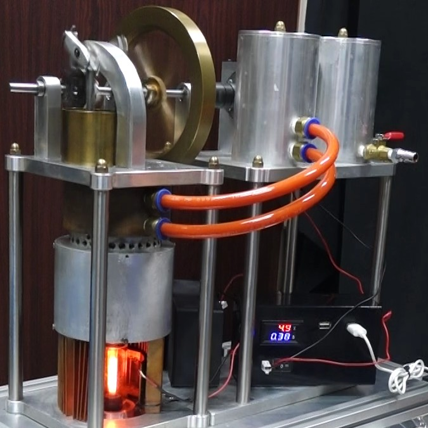

Micro Combustion and Power System

- Design of Micro Combustion System - Platinum Tubular Tube with Perforlated Hole Arrays

- Catalytic Combustion of Bio-Syngas over Platinum Surface

- Cogeneration Power System of Thermophotovaltic Cell Array Combined with Stirling Engine

研究成果:(展開資料)

-

-

-

-

-

-

-

多翰嘉

Email:dorn.killian@orange.fr

研究領域:

Electric Propulsion System

- Pulsed Plasma Thruster with Oblique Electrode Nozzle

- Plasma Measurement - Langmuir Probe and Faraday Cup

- Miniaturizing Electric Propulsion System

碩士論文題目: 電極板夾角對脈衝電漿推進器性能之影響與優化

本論文致力於發展具有不同的電極擴張角度,以及非對稱角度之微型脈衝式電漿推進器(簡稱PPT),選擇四個不同的電極夾角和非對稱配置設置,以檢測其電極結構參數對於推進器性能和可靠性之影響。PPT的原型機設計先前已經完成,本研究主要通過可拆卸和可更換的部件對推進器的推力性能進行改進。通過高速相機的使用已經觀察到並解釋未解決的電漿放電現象,並且提出假設模型。此外,採用田口方法來檢查設計參數對推進器性能和可靠性的影響。

研究成果:(展開資料)

-

-

高孝瑄

Email:a0917987743@gmail.com

研究領域:

Micro Combustion and Power System

- Design of Micro Combustion System - Stainless-Steel and Platinum Tubular Reactor

- Catalytic Combustion of Bio-Syngas over Platinum Surface

- CFD Simulation

- Optimization of Catalytic Combustion Efficiency by Using Surrogate Model

研究成果:(展開資料)

-

翁瑋成

Email:adsl60468@gmail.com

研究領域:

Passive Locating Algorithm and System

- Passive Locating Algorithm for Air to Air/Ground Object Tracking System

- Imaging Stitching Technology

研究成果:

-

-

-

-

-

-

-

-

-

實習生

-

Ritthikon Makaeo 【2022】

Email:ritthikon.m@ku.th

實習期間:2022/12/5~2023/3/24

國籍:泰國

研究主題:

Equivalent Circuit of Vacuum Arc Thruster with Parallel Electrodes Array

-

Romboon Sakulkarunaa 【2018】

Email:rmbn@icloud.com

實習期間:2018/06/01~2018/07/31

國籍:Thailand

研究主題:

Combustion behavior of heavy oil blended with bio-oil

-

Luc JOURDAIN【2018】

Email:luc.jourdain@ensta-bretagne.org

實習期間:2018/06/18~2018/09/17

國籍:France/法國

研究主題:

Optical temperature measurement: two-colour pyrometry

-

Nunthawat SINGCHAI 【2018】

Email:nunthawatsingchai@gmail.com

實習期間:2018/06/01~2018/07/31

國籍:Thailand/泰國

研究主題:

Performance Testing of Micro Vacuum Cathode Arc Thruster

-

Chanapum SUBHAKORN 【2018】

Email:sbk.palm@outlook.com

實習期間:2018/11/17~2019/01/31

國籍:Thailand/泰國

研究主題:

Design, Fabrication & Demonstration of Micro Vacuum Cathode Arc Thruster

-

Phoowis GIJSRIURAI 【2018】

Email:phoowis@hotmail.com

實習期間:2018/11/17~2019/01/31

國籍:Thailand/泰國

研究主題:

Design, Fabrication & Demonstration of Micro Vacuum Cathode Arc Thruster

-

Chanakarn Phoopat 【2022】

Email:chanakarn.phoo@ku.th

實習期間:2022/12/5~2023/3/24

國籍:Thailand

研究主題:

Dual Cable Langmuir Probe

-

-

Antara MENZEL 【2018】

Email:antara.barbara@gmail.com

實習期間:2018/2/19~2018/8/19

國籍:France/法國

研究主題:

Development of Micro-scale Pulsed Plasma Thruster for 3U CubeSAT

-

Damien MICHAUD【2018】

Email:damien.michaud.31@gmail.com

實習期間:2018/06/18~2018/09/08

國籍:France/法國

研究主題:

Development of micro-scale gas-initiated pulse plasma thruster: design of gas propellant feeding system

-

Etienne TESTARD 【2018】

Email:etienne.testard@ensta-bretagne.org

實習期間:2019/6/08 - 2019/8/30

國籍:France

研究主題:

-

Thammathada Wongnak

Email:thammathada.w@ku.th

實習期間:2019/12/6-2020/6/21

國籍:Thailand/泰國

研究主題:

Development of Vacuum-Cathode-Arc-Ignited Pulsed Plasma Thruster

-

Nicolas PERZO【2016】

Email:nicolas.perzo@ipsa.fr

實習期間:2016/6/15~2016/9/15

國籍:France/法國

研究主題:

Design the electrical/chemical duel -mode propulsion chamber

-

Poonyisa PANJATANSAK 【2018】

Email:poonkus40@gmail.com

實習期間:2018/11/17~2019/01/31

國籍:Thailand/泰國

研究主題:

Design, Fabrication & Demonstration of Micro Vacuum Cathode Arc Thruster

-

Siridon CHANGKASIRI 【2018】

Email:changkasiri.peter@gmail.com

實習期間:2018/11/17~2019/01/31

國籍:Thailand/泰國

研究主題:

Design, Fabrication & Demonstration of Micro Vacuum Cathode Arc Thruster

-

Amandine Lavaud 【2019】

Email:amandine.lavaud@ipsa.fr

實習期間:2019/6/10-2019/9/6

國籍:France

研究主題:

The Effect of Nozzle Angle on the Plasma Proprogation in Pulsed Plasma Thruster

-

Nateekan JAREONSOOK【2017】

Email:tong_kssc@hotmail.com

實習期間:2017/1/15~2017/5/16

國籍:Thailand/泰國

研究主題:

Smart Farming Unmanned Aerial Vehicle using Both Lithium-Polymer Battery and Solar Power

-

Thibault HENRY 【2018】

Email:thibault.henry-greard@ensta-bretagne.org

實習期間:2018/06/14~2018/08/24

國籍:France/法國

研究主題:

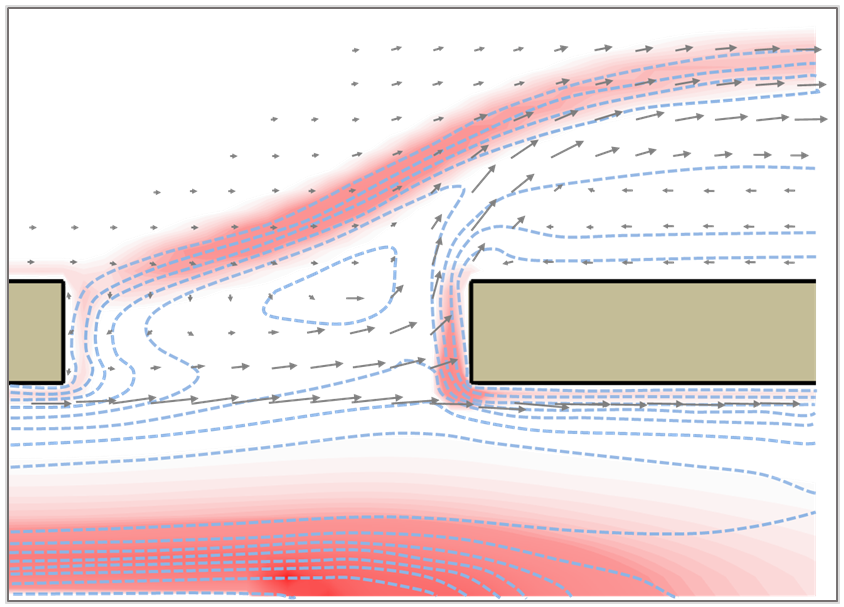

Simluation of Inverse Diffuse Flame via STARTCCM+

-

Victor URBIETA【2017】

Email:victor.urbieta-martin@ipsa.fr

實習期間:2017/8/28~2017/9/22

國籍:France/法國

研究主題:

Preliminary design of two-stage pulsed plasma thruster

-

-

Chandhawat BOONYARD【2017】

Email:earthoz.pdn@gmail.com

實習期間:2017/1/15~2017/5/16

國籍:Thailand/泰國

研究主題:

Smart Farming Unmanned Aerial Vehicle using both lithium-polymer battery and solar power

-

Wattanakorn INTANON【2017】

Email:inta495@gmail.com

實習期間:2017/1/15~2017/5/16

國籍:Thailand/泰國

研究主題:

Smart Farming Unmanned Aerial Vehicle using both lithium-polymer battery and solar power

-

西原 琢矢【2019】

Email:t151844@edu.tut.ac.jp

實習期間:2019/01/07~2019/02/22

國籍:Japan/日本

研究主題:

Design, Fabrication & Demonstration of Micro Combustion for Thermophotovolatic Power System

-

-

前成員

.png)

.png)

.jpg)

.png)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.png)