碩士生: 高健鈞

畢業年分: 2019年7月

論文名稱: 生質燃氣應用於燃燒驅動式微型熱電共生系統之設計與優化(中文) / Design and Optimization of Biosyngas-Combustion-Driven Micro Combined Heat and Power System (英文)

中文摘要:

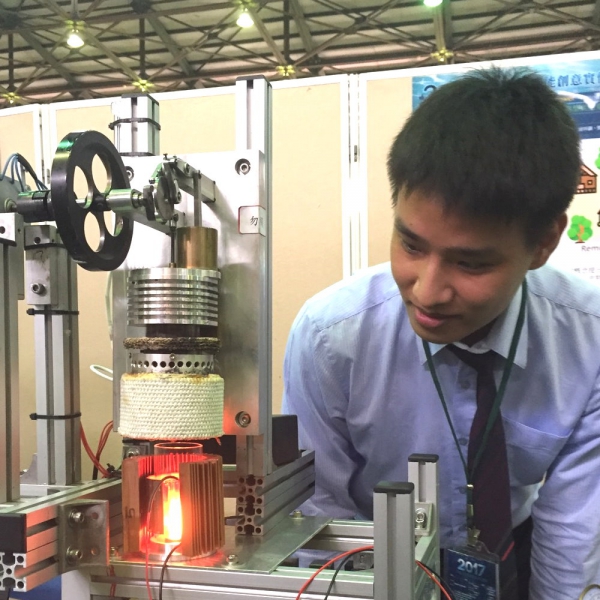

本實驗設置了一熱電共生系統並以田口法提升整體系統效能。本實驗利用熱光電系統以及史特林引擎做為複合式發電系統。熱光電系統的燃燒器為整體系統的主軸,其同心圓的設計能夠將兩側導入不同燃料輸入,並且由鉑金製作而成。本實驗使用氫氣和一氧化碳代替生質燃氣作為輸入燃料至燃燒氣的內環中,並以甲烷代替天然氣體,預混空氣至外環中。設置不同的氫氣-一氧化碳之比例觀察其在燃燒氣中的反應狀況。實驗中內外環流速固定,並將內環氫氣與一氧化碳的比例分成10等分(100%氫氣+0%一氧化碳、90%氫氣+10%一氧化碳、…、10%氫氣+90%一氧化碳),且當量比調整0.6、0.8、1.0、1.2做比較,在當量比較低的情況下,當一氧化碳含量增加時,燃燒器表面的光釋放的改變較不明顯;但當量比大於1.0,一旦增加一氧化碳在內環的比例,所量測到的光釋放有明顯的改變,在純氫氣的條件下光釋放小於30,000W/m2到含有90%的一氧化碳,其光釋放可大於50,000W/m2。

本系統與史特林引擎進行整合,並做整體效率的測試與估算,由於水冷系統的設計與整合使得整體系統效率大幅提升。若僅考慮發電效率,僅有3%的能量轉換,若將整體熱電聯產系統進行分析,則可達33%的總效率。最後,本研究利用田口法進行系統優化,得到系統參數的重要性分析,以及最佳系統效率可達到近40%。

英文摘要:

This study adopted a thermophotovoltaic(TPV) system assembled with a Stirling engine as a combined heat and power(CHP) system and using syngas as input fuel to achieve the goal. A micro TPV combustor was the main component for the CHP system. The micro TPV combustor is a coaxial tube which is made of platinum. H2 and CO premixed with air are the fuel alternative as syngas delivered to inner channel while premixed CH4-air delivered to the outer channel of the micro TPV combustor. Different mixing and equivalence ratios of H2 to CO were set to examine the combustion characteristics and flame behavior through the micro TPV combustor. Due to the higher absorptivity of CO, the rising amount of CO concentration blocked the catalytic surface causing a lower surface reaction of H2. Moreover, in rich-CO condition, H2 reactions promote CO oxidation through the combustion regions resulting in the incandescent emits from the micro TPV combustor more uniform. Although flashback occurs at high-velocity conditions, it has shown that with the presence of CO, it has a higher irradiance and uniformity emission of the micro TPV combustor.

A Stirling engine was assembled with micro-TPV combustor to convert the waste heat to electricity and hot water supply. The CHP system is able to improve the overall efficiency with the assistance of power and heat output installation. At last, the Taguchi method was used to optimize the operation condition of the fuel delivery through the micro TPV combustor. The overall efficiency could reach almost 40%.